Semua produk

-

Aluminium Strip Coil

-

Coil Aluminium Berwarna Warna

-

gulungan aluminium foil

-

Pelat lembaran aluminium

-

Cakram Lingkaran Aluminium

-

film poliester berlapis aluminium foil

-

Plat Kotak-kotak Aluminium Aluminum

-

Lembar Plat Berlian Aluminium Aluminum

-

Lembar Aluminium Timbul

-

Lembaran aluminium anodized

-

Cermin Lembaran Aluminium

-

Wadah aluminium foil

-

Kotak Makan Aluminium Foil

-

Grill BBQ sekali pakai

-

MartinPertama kali kami bekerjasama dengan Yongsheng Aluminium, kami merasa sangat mudah, karena waktu pengiriman barang sangat cepat, dan pengelola bisnis juga sangat profesional.

MartinPertama kali kami bekerjasama dengan Yongsheng Aluminium, kami merasa sangat mudah, karena waktu pengiriman barang sangat cepat, dan pengelola bisnis juga sangat profesional. -

Alice SuPerusahaan kami dan Yongsheng Aluminium telah bekerja sama selama hampir tiga tahun.

Alice SuPerusahaan kami dan Yongsheng Aluminium telah bekerja sama selama hampir tiga tahun. -

ZoeyKami membeli aluminium circle dari Yongsheng Aluminium dan mengirimkannya ke Ghana.

ZoeyKami membeli aluminium circle dari Yongsheng Aluminium dan mengirimkannya ke Ghana. -

Amin MazlumKami telah membeli hampir 500 ton gulungan aluminium warna timbul dari Aluminium Yongsheng.

Amin MazlumKami telah membeli hampir 500 ton gulungan aluminium warna timbul dari Aluminium Yongsheng.

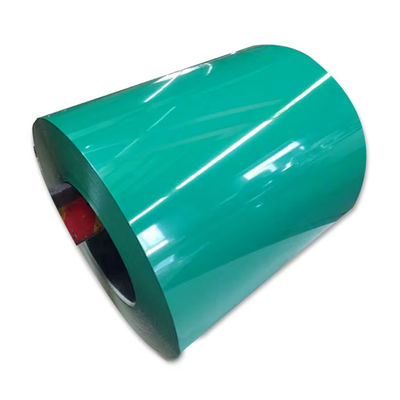

3000 Series PE PVC dilapisi aluminium trim coil roll dicat lembaran aluminium

| Tempat asal | Provinsi Henan, Cina |

|---|---|

| Nama merek | YONGSHENG |

| Sertifikasi | SO,RoHS,MSDS,MTC |

| Nomor model | 1000 3000 Series |

| Kuantitas min Order | 5 ton |

| Harga | 2950-3150 USD/Ton |

| Kemasan rincian | Pengemasan yang layak di laut standar |

| Waktu pengiriman | 7-25 hari setelah konfirmasi pesanan |

| Syarat-syarat pembayaran | L/c, d/a, d/p, t/t |

| Menyediakan kemampuan | 5000 ton per bulan |

Detail produk

| Paduan | 1050, 1060, 1100, 3003, 3004, 3105, dll. | Melunakkan | O-H112 |

|---|---|---|---|

| Ketebalan | 0.2-3mm | Lebar | 10mm-1600mm, dapat dibagi menjadi strip |

| Toleransi | ± 1% | Perawatan permukaan | Lapisan PVDF, Lapisan PE dll. |

| Ketebalan lapisan | Pe≥18 μm, pvdf≥25 μm | Warna | Perak, perunggu, hitam, emas, biru, abu -abu, cerah, dll |

| Sedang mengemas | Ekspor palet kayu yang layak laut | Mencicipi | bebas |

| Menyoroti | Koil trim aluminium berlapis PVC,roll foil aluminium yang dicat,Kumparan aluminium yang dilapisi warna |

||

Deskripsi Produk

3000 Series PE PVC dilapisi aluminium trim coil roll dicat lembaran aluminium

Lembaran aluminium berkinerja tinggi yang dirancang untuk aplikasi industri dan arsitektur dengan ketahanan cuaca dan daya tahan yang unggul.

Spesifikasi Produk

| Paduan | Ketebalan (mm) | Ketebalan Lapisan (mikron) | Lebar (mm) | Temperature |

|---|---|---|---|---|

| A1050,A1060,A1070,A1100,A1235,A1245 | 0.15-3.0 | PE≥14 PVDF≥25 | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 |

| 3.0-12.0 | - | 20-2200 | H111,H112 | |

| A3003, A3004, A3105 | 0.2-4.0 | - | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 |

| 4.0-12.0 | - | 20-2200 | H111,H112 | |

| A5052, A5083, A5754, A5005 | 0.2-4.0 | - | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 |

| 4.0-12.0 | - | 20-2200 | H111,H112 | |

| A6061, A6082, A6063 | 0.15-12 | - | 20-2200 | T6,T4,T651 |

| A8011,1235 | 0.006-0.2 | - | 20-2200 | O,H14,H18,H24 |

Lapisan akhir:PVDF (Polyvinylidene Fluoride), PE (Polyester)

Kekerasan Lapisan:Lebih dari HB (resistensi pensil)

Keuntungan Utama

- Tahan suhu tinggi

- Tahan terhadap cuaca

- Tahan gosok

- Isolasi suara

- Buktinya asam atau alkali

- tahan api

- Bahan ringan untuk konstruksi dan pemasangan yang mudah

Identitas:405MM, 505mm

Kemasan:Ekspor pallet kayu, kotak kayu

Standar:ASTM-B209, EN573-1, GB/T3880.1-2006

Perbandingan PE vs PVC Aluminium Lapisan

Lembaran aluminium bertekstur PE dan lembaran aluminium bertekstur PVC keduanya termasuk lembaran aluminium bertekstur permukaan dengan lembaran paduan aluminium sebagai bahan dasar inti.Perbedaan inti terletak pada bahan lapisan.

Lembar aluminium berlapis PE

Keuntungan Utama:

- Ketahanan cuaca yang sangat baik dan ketahanan korosi untuk lingkungan luar dan keras

- Fleksibilitas yang baik dan kemampuan penyesuaian pengolahan yang kuat untuk persyaratan bentuk yang kompleks

- Stabilitas jangka panjang yang tinggi dengan biaya pemeliharaan rendah

- Ramah lingkungan, cocok untuk digunakan baik di dalam maupun di luar ruangan

Kelemahan Utama:

- Kekerasan permukaan yang lebih rendah dan ketahanan goresan

- Tekstur dekoratif tidak memiliki efek tiga dimensi

- Biaya produksi yang lebih tinggi dibandingkan dengan PVC

Koil Aluminium Lapisan PVC

Keuntungan Utama:

- Kekerasan permukaan yang tinggi dan ketahanan goresan yang sangat baik

- Tekstur tiga dimensi yang kuat dengan warna-warna cerah untuk efek dekoratif yang ditingkatkan

- Biaya produksi yang lebih rendah dengan proses pelapisan sederhana

Kelemahan Utama:

- Ketahanan cuaca yang buruk dan masa pakai yang lebih pendek di luar ruangan

- Fleksibilitas dan kemampuan pemrosesan terbatas

- Ketahanan panas yang buruk, tidak cocok untuk lingkungan suhu tinggi

- Potensi pelepasan zat berbahaya, yang membutuhkan pengujian lingkungan

Rekomendasi pembelian

- Penggunaan jangka panjang di luar ruangan(dinding eksterior, iklan luar): Pilih lembaran aluminium berlapis PE dengan lapisan jenis tahan cuaca

- Dekorasi interior dengan anggaran terbatas(pakaian, vitrin): Pertimbangkan lembaran aluminium berlapis PVC dengan laporan pengujian lingkungan (RoHS, GB 18585)

- Persyaratan pengolahan yang kompleks(membengkok, stamping): Harus memilih lembaran aluminium PE dilapisi (PVC rentan terhadap retakan)

- Lingkungan suhu tinggi(pawon, sumber panas): PVC dilarang; PE direkomendasikan

Pedoman Pemeliharaan

Lembar aluminium berlapis PE

- Bersihkan dengan air atau pembersih netral

- Hindari sikat dengan bulu yang keras untuk mencegah goresan

- Penggunaan di luar ruangan: Bersihkan setiap 1-2 tahun untuk memperpanjang umur

Lembar Aluminium Lapisan PVC

- Hindari kontak dengan suhu tinggi (air panas, oven)

- Bersihkan dengan kain kering atau pembersih alkali lemah

- Hindari pelarut yang kuat (benzin, dll.)

- Penggunaan di luar ruangan: Periksa setiap enam bulan; ganti segera jika lapisan retak

Gambar Produk

Aplikasi Produk

Rekomendasi Produk